Welcome to

“virtual factory tour”

of the Sumioka Foods Group

Thank you for your interest in the Sumioka Foods Group.

In the “virtual factory tour,” you can experience our factory from a 3D perspective.

Please take a look at the production site with an established system to maintain high quality by fusing the know-how that we have cultivated and the latest technology.

The more you know, the more you can enjoy the factory tour! Hygiene management of the Sumioka Foods Group

We take pre-emptive measures against mistakes and errors!

Sumioka Foods Group’s “proactive” hygiene management measures

Three levels of hygiene control

Division of work area and change of work clothes ensure thorough prevention of foreign matter contamination!

A factory is divided into three areas according to the hygiene level, where work clothes are changed, hands are washed, and an air shower is provided. Workers are dressing and undressing in separate rooms.

We take careful preventive measures; for example, in order to enter the Level 3 area, workers change clothes twice, go through four rooms for dressing and undressing, and wash their hands and undergo an air shower each time they enter the rooms.

Wall, wall, and wall...

Risk management by dividing into small rooms

It has a maze-like atmosphere, since each manufacturing process is divided and many small rooms are lined up. These small rooms ensure the prevention of foreign matter contamination.

Silver room

Wash completely after work

In order to prevent contamination by raw materials of other products and allergens, the entire work room is washed after each task. That is why the walls are made of stainless steel.

Which factory would you like to visit

on the virtual factory tour?

[Operation guide]

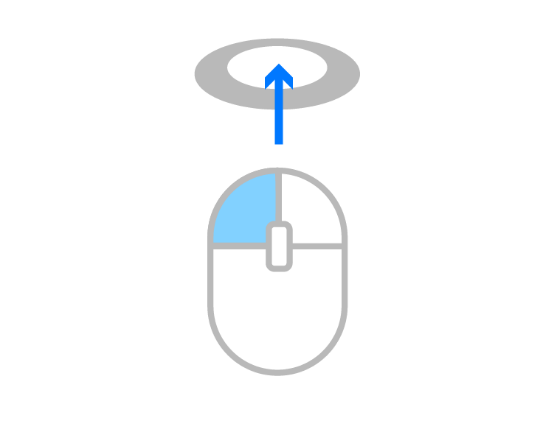

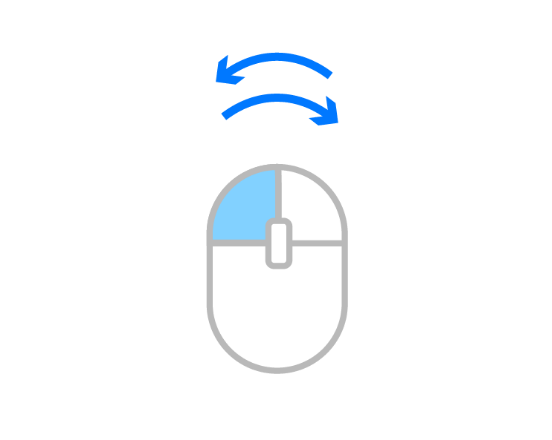

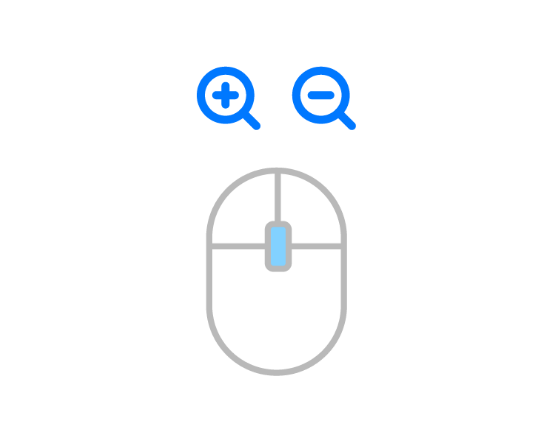

Operation on a personal computer

Click the ring on the floor of the entire space to move around.

Click and drag to look around the space.

Use a scroll wheel to zoom in/out.

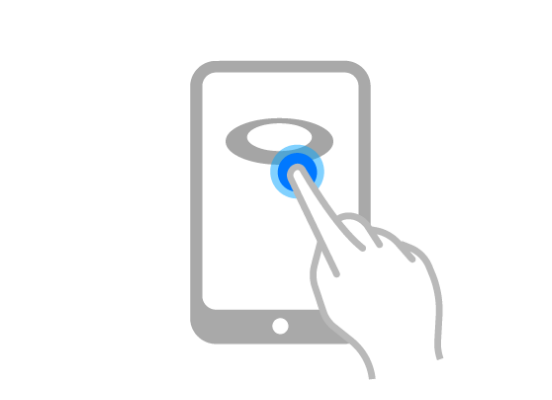

Operation on a smartphone

Tap the ring on the floor of the entire space to move around.

Flick the screen to look around the space.

Pinch in/out the screen to zoom in/out.

[System requirements]

We recommend a wired or Wi-Fi internet connection for viewing.

[Important notes]

Copying or using this content without permission is strictly prohibited.

Shooting locations: Hamakita Factory of Sumioka Foods Corporation, Hamamatsu Factory of ES Foods Corporation

* The video of the manufacturing process is composed of contents taken before March 2022.

Copyright © SUMIOKA FOODS CORPORATION. All rights reserved.

Frequently asked questions about machines

- Q Can you subdivide and package large sizes?

- We own a large three-side sealer bag packaging machine. → Packaging form

- Q I am considering the pouch filling of powder. What is the maximum filling capacity?

- In the case of powder, it can be filled up to 1,000 g. → Packaging form